Your current browser version is too low, in order to bring you a better browsing effect, please use a higher version browser

Screw and sleeve are the key parts of plastic machinery such as injection and extruder molding machine, whose structure and quality directly affect the working efficiency and product quality of the extruder or injection molding machine.Ceramic particles and glass fibers are widely used as hard strengthening phases in the field of engineering resin, which have high requirements for wear resistance of parts.High quality screw material is one of the basic conditions to ensure the efficient operation of plastic machinery.

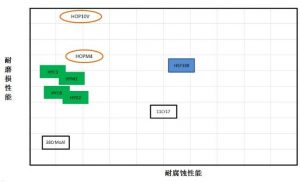

AT&M-HEYE adopts a variety of processes to produce high-quality screw sleeve materials, forming an overall solution for material selection, providing better choices for plastic machinery parts manufacturers, and reducing costs and increasing efficiency for each screw sleeve product.

The steel used in the production of such key parts has excellent strength,toughness ratio and machinability and grindability. Meanwhile, it possesses a balance of excellent corrosion resistance, wear resistance and good dimensional stability.

Typical applications are as below:

• Screw of extruder, injection molding machine and other parts,

• Food processing tools

• Medical surgical instruments

• Industrial shear blade

• Wear resistant and corrosion resistant parts

Typical Application pictures are as below:

| Annealing Hardness≤300HB |

| Macrostructure and Defect Rating Table | ||

| Steel Diameter or Side Length/mm | Loose Center≤ | Ingot Segregation≤ |

| Diameter/Length | Central Porosity | Ingot Segregation |

| ≤80 | 3.0 | 3.0 |

| >80~150 | 3.5 | 3.0 |

| >150-250 | 4.0 | 4.0 |

| >250-400 | 4.5 | 4.0 |

| >400 | Agreement | protocol |

| Varieties and Specifications Table | ||

| Varieties | (mm)Specifications | Surface State |

| Forged round bar | φ80-400 | Grinding wheel peeling/wagon |

| Hot rolled round bar | φ21-95 | Peeling/skinning |

| Forgings | Round φ(50-300)×(10-300) | Black leather/pre-processed |

| Rectangular (20-200) × (5-80) | ||

| Nonmetallic inclusion rating sheet | ||

| Categories | Fine≤ | Coarse≤ |

| A | 2.5 | 2.0 |

| B | 2.5 | 2.0 |

| C | 1.5 | 1.5 |

| D | 2.5 | 2.0 |

| Comparison Table of Decarburization Depth | |

| Steel diameter or side length | Total decarburization depth, ≤ |

| Diameter/Length | Decarburization depth |

| 5~150 | 0.2+2% |

| >150 | Agreement |